For over 80 years, Bowman has provided quality heat exchangers for the marine industry. Now as the industry seeks to lower CO2 emissions, Bowman is also providing cooling solutions for the new generation of advanced marine electric and hybrid propulsion systems and hydrogen fuel cell technology which is being developed to meet increasingly stringent emissions regulations.

The following information offers a general guide to the performance and dimensions of our standard range of marine grade shell and tube heat exchangers.

For more detailed information on additional configurations, please download the product brochure, or contact our technical sales team on +44(0)121 359 5401, or email [email protected].

Easy Product Selection

Boats with electric and hybrid propulsion systems are often designed to operate with sea water temperatures of 30 °C plus, making selecting the right heat exchanger critical. Whilst the tables below list typical performance examples at given temperatures and flow rates, they are intended as a general guide only.

However, by supplying the following information, we can provide a computer-aided product selection, to recommend the most appropriate heat exchanger for your requirements:

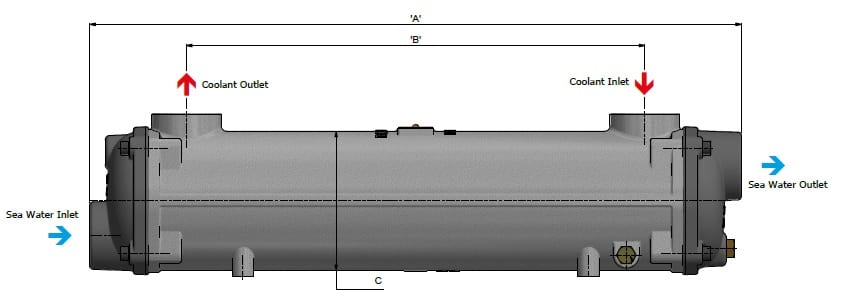

Note – Dimensions in the tables refer to standard three-pass, sea water heat exchangers. For part numbers and more detailed drawings, please download the brochure or contact the technical sales team.

Both tables include products that are suitable for cooling electrical propulsion systems and equipment with sea water but the first table includes heat exchangers with a cupronickel tube stack and the second table includes part numbers for heat exchangers fitted with titanium tube stacks.

Cupronickel heat exchangers are rated to a maximum pressure of 20 bar on the coolant side and 16 bar on the sea / fresh water side of the cooler at a maximum temperature of 110 °C. Titanium heat exchangers are rated to 4 bar pressure at a maximum temperature of 95 °C.

Larger heat exchangers are also available for higher heat loads. Download the brochures or contact our sales team for more information.

| Type | Heat Dissipated (kW) | Dim. A (mm) | Dim. B (mm) | Dim. C (mm) | Weight (kg) |

|---|---|---|---|---|---|

| EC80-3875-1 | 3 | 174 | 60 | 84 | 2.4 |

| EC100-3875-2 | 7 | 260 | 140 | 84 | 3.2 |

| EC120-3875-3 | 11 | 346 | 226 | 84 | 3.8 |

| EC140-3875-4 | 15 | 444 | 324 | 84 | 4.8 |

| EC160-3875-5 | 19 | 572 | 452 | 84 | 5.7 |

| FC80-3876-1 | 11 | 272 | 116 | 108 | 5.5 |

| FC100-3876-2 | 16 | 358 | 202 | 108 | 6.3 |

| FC120-3876-3 | 22 | 456 | 300 | 108 | 7.3 |

| FC140-3876-4 | 29 | 584 | 428 | 108 | 9.4 |

| FC160-3876-5 | 37 | 730 | 574 | 108 | 11.0 |

| FG80-3877-1 | 24 | 374 | 196 | 128 | 8.5 |

| FG100-3877-2 | 32 | 472 | 294 | 128 | 10.0 |

| FG120-3877-3 | 43 | 600 | 422 | 128 | 12.0 |

| FG140-3877-4 | 53 | 746 | 568 | 128 | 14.5 |

| FG160-3877-5 | 65 | 924 | 746 | 128 | 17.5 |

| GL140-3878-2 | 50 | 502 | 272 | 162 | 18.0 |

| GL180-3878-3 | 66 | 630 | 400 | 162 | 21.0 |

| GL240-3878-4 | 82 | 776 | 546 | 162 | 25.0 |

| GL320-3878-5 | 100 | 954 | 724 | 162 | 30.0 |

| GL400-3878-6 | 121 | 1156 | 926 | 162 | 36.0 |

| GL480-3878-7 | 136 | 1360 | 1130 | 162 | 42.0 |

| GK190-3879-3 | 98 | 674 | 370 | 198 | 34.0 |

| GK250-3879-4 | 125 | 820 | 516 | 198 | 39.0 |

| GK320-3879-5 | 153 | 998 | 694 | 198 | 46.0 |

| GK400-3879-6 | 181 | 1200 | 896 | 198 | 54.0 |

| GK480-3879-7 | 206 | 1404 | 1100 | 198 | 62.0 |

| GK600-3879-8 | 238 | 1708 | 1404 | 198 | 74.0 |

| Type | Heat Dissipated (kW) | Dim. A (mm) | Dim. B (mm) | Dim. C (mm) | Weight (kg) |

|---|---|---|---|---|---|

| EC80-5204-1 | 3 | 174 | 60 | 84 | 1.5 |

| EC100-5204-2 | 7 | 260 | 140 | 84 | 2.1 |

| EC120-5204-3 | 11 | 346 | 226 | 84 | 2.6 |

| EC140-5204-4 | 15 | 444 | 324 | 84 | 3.2 |

| EC160-5204-5 | 19 | 572 | 452 | 84 | 3.8 |

| FC80-5205-1 | 11 | 272 | 116 | 108 | 3.5 |

| FC100-5205-2 | 16 | 358 | 202 | 108 | 4.2 |

| FC120-5205-3 | 22 | 456 | 300 | 108 | 5.2 |

| FC140-5205-4 | 29 | 584 | 428 | 108 | 6.5 |

| FC160-5205-5 | 37 | 730 | 574 | 108 | 8.0 |

| FG80-5206-1 | 24 | 374 | 196 | 128 | 5.7 |

| FG100-5206-2 | 32 | 472 | 294 | 128 | 7.0 |

| FG120-5206-3 | 43 | 600 | 422 | 128 | 8.4 |

| FG140-5206-4 | 53 | 746 | 568 | 128 | 10.4 |

| FG160-5206-5 | 65 | 924 | 746 | 128 | 12.6 |

Technical sales brochure includes product information, ratings charts, drawings and dimensions for the range of shell and tube heat exchangers for electric & hybrid marine propulsion.

The brochure provides an overview of the products that are used for marine applications including engine and transmission coolers and heat exchangers for hydraulic deck machinery.

Pioneering hydrogen fuel cell vessels rely on sophisticated technology - read more in this published article.